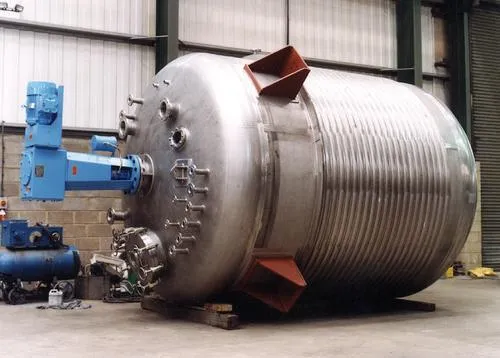

Mixing Vessels with Limpet coil

Varadraj Manufacturing specializes in Mixing Vessels with a Limpet coil type of tank or vessel equipped with a limped coil (often referred to as a helical coil) inside the vessel for mixing and heating or cooling purposes. These are commonly used in various industries, including chemical, pharmaceutical, food, and beverage processing.

The limp coil also serves to enhance the mixing process. The coil’s shape promotes better fluid circulation, helping to evenly distribute heat or coolant within the vessel and improving the uniformity of mixing. This can be particularly beneficial for processes like emulsification or suspension.

Applications and Advantages

- Heating or Cooling: The limp coil inside the mixing vessel often carries hot or cold fluid to regulate the temperature of the contents of the vessel. For example, the coil can carry steam (for heating) or a cooling medium (such as water or glycol) to maintain the desired temperature during chemical reactions or mixing processes.

- Efficient Heat Transfer: The coiled shape of the limp coil increases the surface area for heat exchange between the coil and the fluid inside the vessel, improving heat transfer efficiency. This is particularly important in processes that require precise temperature control, such as in polymerization, fermentation, or crystallization.

- Mixing Enhancement: In some designs, the limp coil also serves to enhance the mixing process. The coil’s shape promotes better fluid circulation, helping to evenly distribute heat or coolant within the vessel and improving the uniformity of mixing. This can be particularly beneficial for processes like emulsification or suspension.

We are committed to delivering top-notch solutions that enhance your production efficiency and meet your technical wishes. Contact us now for more information or a quote! Let Varadraj Industries take your operations to the next level.