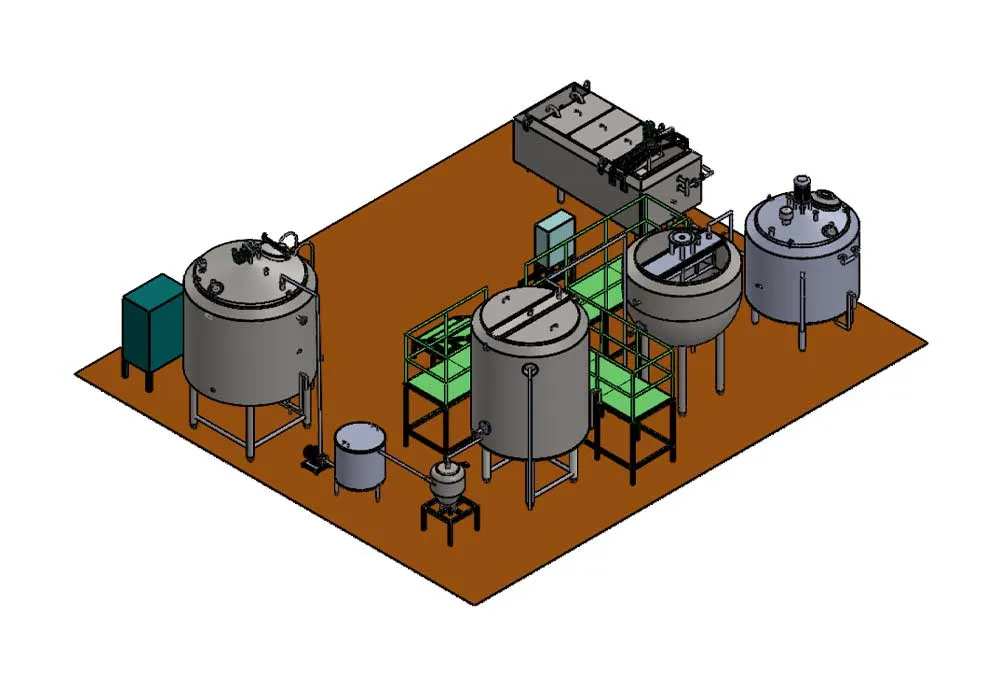

Ghee Plant Equipments

A ghee plant requires equipment like a cream separator, butter churn, melting kettle, ghee boiler, settling and storage tanks, vacuum dehydrator (optional), filter press, and packaging machine. Additional systems include steam boilers and CIP systems to ensure efficient, hygienic ghee production.

Why choose us?

- Our Ghee Plant Equipment providers and exporters offer complimentary home delivery to all our clients, along with a 100% satisfaction guarantee.

- The Ghee Plant producers have been catering to clients for the past thirty years with our top-quality products.

- Ghee Plant Equipment manufacturers are known for our high-quality products and services.

- Our equipment is crafted by specialists and thoroughly evaluated by our team of professionals to guarantee compliance with all global standards.

A ghee plant requires specialized equipment for processing milk or cream to produce ghee, which is a clarified form of butter widely used in South Asia and parts of the Middle East. The equipment setup in a ghee plant depends on the scale of production and specific processing techniques, but generally includes the following:

1. Cream Separator

- Purpose: To separate cream from the milk. The cream is then further processed into butter, which will be clarified to make ghee.

- Function: It uses centrifugal force to separate the cream from the skimmed milk.

2. Butter Churn

- Purpose: Converts the cream into butter by churning it.

- Function: It agitates the cream to break the fat globules, resulting in butter and buttermilk.

3. Melting Kettle or Butter Melting Vat

- Purpose: Used to melt the butter before the clarification process.

- Construction: Often made of stainless steel, with a jacketed design for indirect heating, ensuring uniform melting.

4. Ghee Boiler / Clarification Tank

- Purpose: To heat and clarify the melted butter, separating the milk solids from the fat.

- Function: Uses controlled heat to evaporate water and skim off impurities (curd or milk solids). The clarified fat left is ghee.

- Construction: Often jacketed for steam or oil heating, with mechanical or manual stirring to ensure even heating.

5. Ghee Settling Tank

- Purpose: To allow the molten ghee to settle after clarification, ensuring separation of any remaining solids or impurities.

- Design: Comes with conical bottoms to allow for easy drainage of impurities.

6. Ghee Storage Tank

- Purpose: Used to store ghee in liquid form before it is packed or transferred.

- Material: Typically made from stainless steel to ensure hygiene and prevent contamination.

7. Vacuum Dehydrator (Optional)

- Purpose: To remove moisture from the ghee in an accelerated process.

- Function: Operates under vacuum conditions to boil off any residual moisture without overheating the ghee.

8. Ghee Packaging Machine

- Purpose: For filling and sealing ghee in various types of containers, including tins, bottles, or pouches.

- Automation: Varies based on production scale, from semi-automatic to fully automatic filling and sealing machines.

9. Cooling Systems (Optional)

- Purpose: To cool the ghee after clarification and before packaging.

- Construction: A cooling tunnel or chamber may be used for large-scale production.

10. Filter Press

- Purpose: To remove fine impurities from the ghee.

- Function: Uses fine mesh or cloth filters to capture remaining particulate matter before the ghee is packed.

Additional Considerations:

- Steam Boilers: Used to provide steam for heating various processes like melting butter or clarifying ghee.

- Thermic Fluid Heaters: These provide controlled heating for the clarification process.

- CIP (Clean-in-Place) Systems: For cleaning the equipment efficiently between production cycles, and maintaining hygiene standards.

Each piece of equipment plays a critical role in ensuring that the production of ghee is efficient, hygienic, and of high quality.